Warning: Cannot modify header information - headers already sent in /home/u278635817/domains/myhousegarden.com/public_html/wp-content/plugins/artigosgpt/artigosgpt.php on line 28454

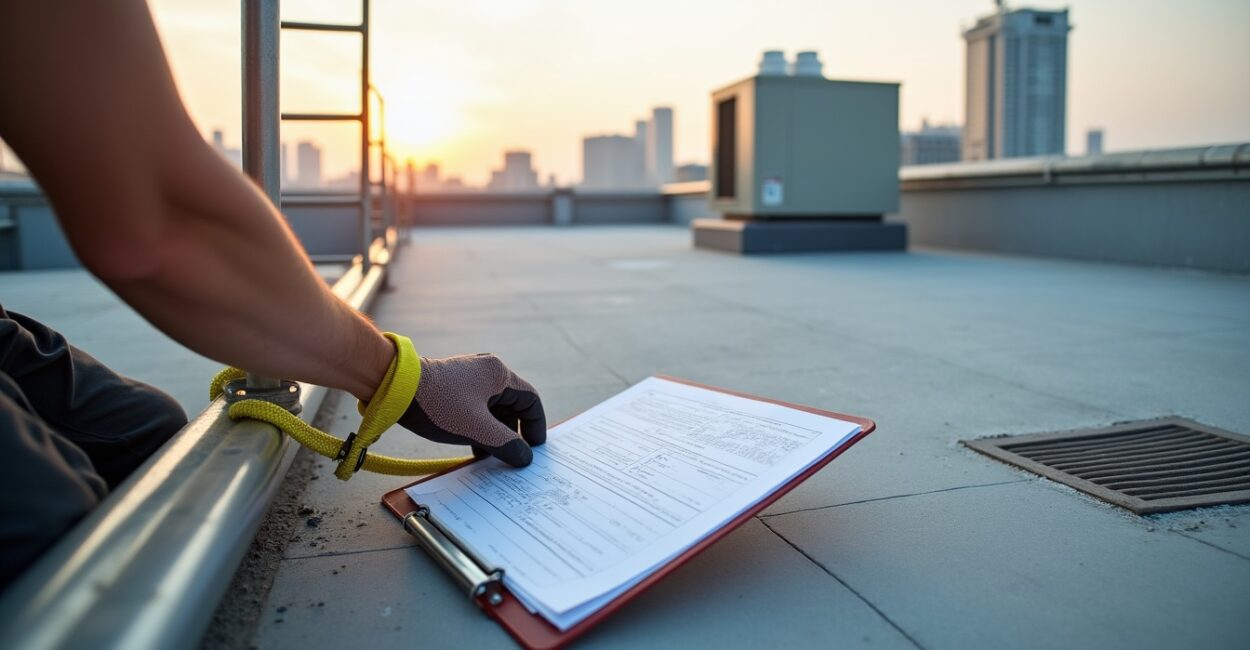

The hum of rooftop life—HVAC units, solar panels, and a risky edge—beckons both curiosity and caution. Rooftop safety matters because one misstep turns a view into a tragedy; this article shows what to inspect and why.

In this guide you’ll learn a practical new rooftop safety checklist: inspect guardrails, wind anchors and drains, and understand recent changes like Chicago’s updated fire-code inspections for rooftop access. Expect clear steps, quick wins, and authoritative pointers.

Why rooftop safety matters today

Rooftop safety blends fall protection, access control, and weather resilience. Guardrails, anchor points, and drainage prevent accidents and property damage while ensuring compliance with local codes.

Risk and responsibility

Owners and managers must prioritize inspection and maintenance to reduce liability, keep tenants safe, and avoid costly fines from building departments and insurers.

Regulation and best practice

Codes like fire inspections, OSHA guidance, and local ordinances shape rooftop access rules. Regular audits and documented checks demonstrate due diligence and care.

Core components of a rooftop safety checklist

Start with the essentials: guardrails, wind anchors, drains, skylight protection, and secure access points. Each piece matters for structural and personal safety.

- Confirm guardrail height, continuity, and fasteners.

- Verify wind anchor integrity and corrosion-free hardware.

- Clear drains and test backups to prevent pooling.

Guardrails and parapets

Inspect for loose posts, missing midrails, and rusted anchors. Ensure parapet caps and through-bolts remain secure and protective under foot traffic.

Anchors and fall-arrest points

Check certification tags, load ratings, and installation torque. Replace suspect anchors immediately and log every change for records and audits.

Practical inspection workflow for rooftop safety

Adopt a consistent route: access point, perimeter, equipment zones, and drainage. Document findings with photos and timestamps for accountability and repairs.

Pre-inspection preparation

Gather PPE, ladders, radios, and inspection forms. Notify building occupants and follow lockout procedures for rooftop machinery.

On-roof procedure

Walk the roof systematically, test anchors, run a water test for drains, and note corrosion, cracks, or missing hardware immediately.

Step-by-step emergency readiness (quick actions)

Prepare for sudden wind events, falls, or blocked egress by rehearsing response steps and ensuring access for first responders. This improves survival odds and limits damage.

- Secure the scene and account for personnel.

- Call emergency services if injuries occur.

- Use anchors and lifelines to retrieve first aid safely.

- Document incident details and notify management.

- Schedule immediate repairs to failed components.

Emergency equipment and drills

Have stretchers, rescue harnesses, and clear rooftop signage. Regular drills keep teams confident and reduce panic during incidents.

Coordination with responders

Share rooftop layouts with local fire and rescue teams. Chicago and other cities increasingly require documented rooftop access plans for emergency services.

Maintenance, documentation, and codes

Combine routine maintenance with compliance checks: roof membrane care, connector torque checks, and fire-code inspections. Keep records for audits and insurance claims.

- Schedule quarterly inspections for critical components.

- Store photo logs, repair receipts, and inspection tags.

- Follow NFPA, OSHA, and local fire-code guidance.

Recordkeeping best practices

Use digital logs with timestamps and geotagged photos for each inspection. Maintain a centralized archive accessible to stakeholders and inspectors.

Aligning with code updates

Monitor local amendments like Chicago’s updated rooftop fire-code inspections. Integrate new requirements into your checklist and training materials.

Equipment, retrofits, and cost-effective upgrades

Invest in durable guardrails, corrosion-resistant anchors, and high-capacity drains to extend roof life. Small upgrades often prevent large losses from water or wind damage.

| Upgrade | Benefit | Estimated Lifespan |

|---|---|---|

| Galvanized guardrails | Reduced corrosion, consistent barrier | 15–25 years |

| Stainless-steel anchors | Higher load capacity, less maintenance | 20+ years |

| Enhanced drainage kits | Prevents ponding and membrane failure | 10–20 years |

Choosing resilient materials

Prefer stainless steel and powder-coated finishes for rooftop hardware. Materials that resist salt, freeze-thaw cycles, and UV preserve safety components.

Budgeting for longevity

Prioritize anchor replacement and drainage fixes in annual budgets to avoid emergency spending after storms or regulatory demands.

Inspection checklist example and tools

Use the checklist below during each rooftop visit: verify guardrails, test wind anchors, inspect drains, and confirm safe rooftop access points. Keep records digital.

- Confirm secure rooftop access and signage.

- Test each anchor and record load-tag info.

- Clear drains, inspect membranes, and photograph issues.

Tools to carry

Bring torque wrenches, inspection tags, water hose for drain tests, and a phone for photos and emergency calls. Lightweight kits improve mobility.

Digital inspection apps

Log faults, assign repairs, and maintain histories with mobile apps. These tools help during audits and speed up compliance reporting.

Conclusion

Rooftop safety saves lives, money, and reputation. A focused checklist that inspects guardrails, wind anchors, and drains—while aligning with updated codes like Chicago’s—turns risk into control.

Return to your rooftop with confidence: inspect, document, repair, and train. That simple rhythm transforms anxiety into assurance and keeps views safe for everyone.

FAQ

How often should rooftop safety inspections occur?

Inspections should happen quarterly for general checks and after major storms or roof work. High-risk rooftops may need monthly reviews, while detailed annual inspections should include load tests for anchors and full documentation for compliance and insurance purposes.

What are the key signs of failing guardrails or anchors?

Look for loose bolts, bent posts, rust at connection points, missing midrails, and visible cracks around anchors. Any movement under load testing indicates replacement is necessary to prevent failure and ensure rooftop occupants stay protected.

How do I test rooftop drains effectively?

Run a water test from the highest rooftop quadrant toward drains, observe flow rate, and remove debris. Ensure secondary overflow paths work and record pooling locations that indicate membrane issues requiring prompt repair.

Does Chicago require special rooftop fire-code inspections?

Chicago updated its fire-code inspections to tighten rooftop access and emergency egress requirements. Building owners must provide clear access plans, documented inspections, and compliant pathways for responders to reduce rescue delays and fines.

Which authoritative resources help shape rooftop safety standards?

Consult OSHA fall-protection guidance, NFPA standards for rooftop equipment access, and local building departments. These resources provide technical specs and compliance frameworks for guardrails, anchors, and emergency access planning.

Authoritative sources: OSHA guidance on fall protection (OSHA Falls), NFPA rooftop access recommendations (NFPA), and Chicago Fire Department code updates (Chicago.gov).